2019 China New Design Self-aligning Pipe Welding Turning Rotator Rolls

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and growth, we will build a prosperous future collectively with your esteemed firm for 2019 China New Design Self-aligning Pipe Welding Turning Rotator Rolls, We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers.

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and growth, we will build a prosperous future collectively with your esteemed firm for Pipe Turning Rolls, Welding Rotator, Welding Turning Rolls, We’ve got more than 8 years of experience in this industry and have a good reputation in this field. Our products and solutions have won praise from customers worldwide. Our aim is to help customers realize their goals. We’re making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Quickly Details:

Type: Self-aligning Welding Rotator

Brand: Sanlian Heavy Industry

Condition:100% brand new

Model number:HGZ

Capacity: 5Ton – 150Ton

Consist: (1) Drive unit , (1) Idler unit , (1) Control box with hand panel

Voltage:110V-600V

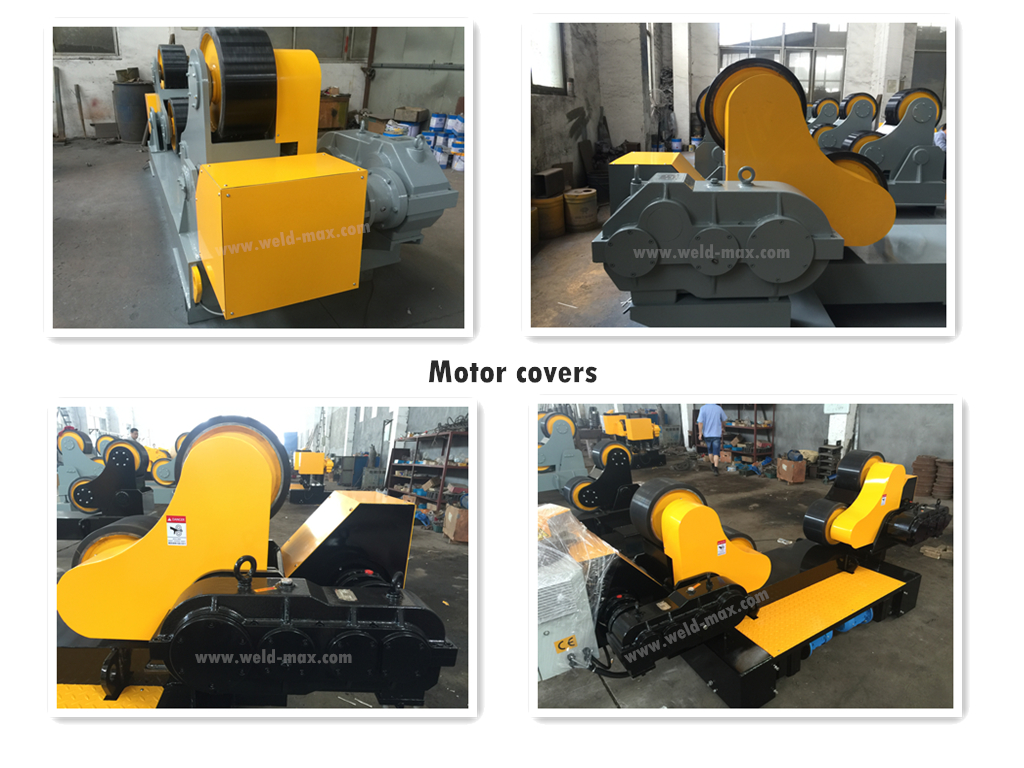

Painting Color:Yellow & Blue /Yellow & Grey / Yellow & Black / Red&Black

Place of origin:Wuxi , China(Mainland)

Application :

Welding Rotator major used in cylinder welding ,such as Marine,Oil&Gas ; Offshore,Petro Chemical ; Plate Heat Exchanger ; Charged air cooler ; Pressure Vessel ; Boiler ; Pipe system&Steel works etc.

Product Description

The welding rotator is applied in the manual welding and automatic welding for metallic tank, vessel and pipe, it is the necessary for the pressure vessel manufacturing. It has the good character as advanced technology, reliable quality, easy operation and so on. The tank rotator has two types including self-aligning and adjustable. It can suit for the difference diameter tank within the range and achieve the stepless speed adjusting under the setted welding parameter, which has the good character as small noise on the transmission and steady rotation for the working table.

Technical Parameters

|

Type |

Max loading (kg) | Vessel diameter(mm) | Dia. and width of the wheel(mm) |

Roller linear velocity(m/h) 6-60 |

Power of motor(kw) |

|

| Rubber rollers | Metal rollers | |||||

|

HGZ-5 |

5,000 |

Φ250-2300 | Φ250×100 | 2×Φ240×20 |

0.75 |

|

|

HGZ-10 |

10,000 |

Φ320-2800 | Φ300×120 | 2×Φ290×25 |

1.1 |

|

|

HGZ-20 |

20,000 |

Φ500-3500 | Φ350×120 | 2×Φ340×30 |

1.5 |

|

|

HGZ-40 |

40,000 |

Φ600-4200 | Φ400×120 | 2×Φ390×40 |

3.0 |

|

|

HGZ-60 |

60,000 |

Φ750-4800 | Φ450×120 | 2×Φ440×50 |

4.0 |

|

|

HGZ-80 |

80,000 |

Φ850-5000 | Φ500×120 | 2×Φ490×60 |

2X3 |

|

|

HGZ-100 |

100,000 |

Φ1000-5500 | Φ500×120 | 2×Φ490×80 |

2X3 |

|

|

HGZ-150 |

150,000 |

Φ1000-6000 | / | Φ620×220 |

2X4 |

|

|

HGZ-250 |

250,000 |

Φ1800-7500 | / | Φ660×260 |

2X5.5 |

|

|

HGZ-500 |

500,000 |

Φ1800-8000 | / | Φ750×400 |

2X7.5 |

|