CNC Waterjet cutting machine

Quickly Details:

Type:CNC Waterjet cutting machine

Brand:Sanlian Heavy Industry

Condition:100% brand new

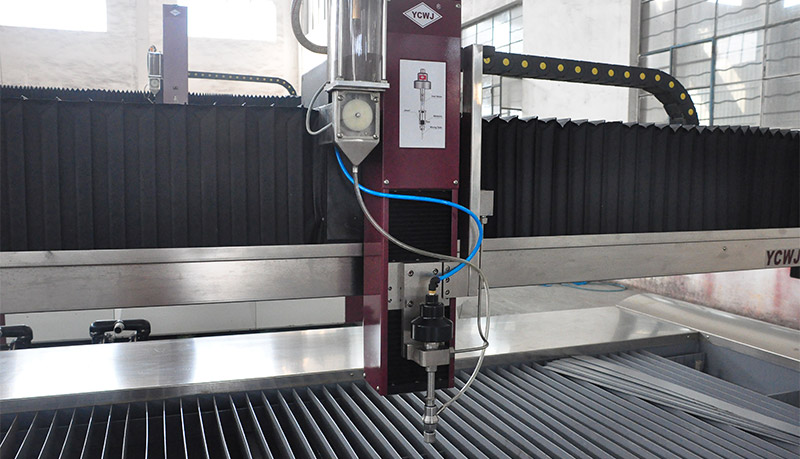

Model number:YCWJ

Consist: HP System / Cutting table / CNC Controller

Voltage:110V-600V

Painting Color:Yellow & Blue /Yellow & Grey / Yellow & Black / Red&Black

Place of origin:Wuxi , China(Mainland)

The advantage of Waterjet cutting machine

1) Can be transfer the drawing to cutting quickly

2) Quickly position-some or few fixing equipments

3) High accuracy-reduce the re-cutting

4) Quicker cutting speed

5) In no need of fabrication for the working parts

6) Safer for the operator and circumstance steam, dust , smog,etc

7) Cool cutting-no heat will be produced

8) Clear processing, in no need of clear the working parts again

9) Good cutting finishes-in no need of application the cutting finishes again

10) Narrow cutting gap

11) Quickly calibration and easier versatility way of cutting. It has been proved that it can be used

In mass production in the ideal system

12) Fit for CAD/CAM software

13) Waterjet cutting machine can cut almost all the material. It can cut the thickness max to 200mm

Brand Using

Overview

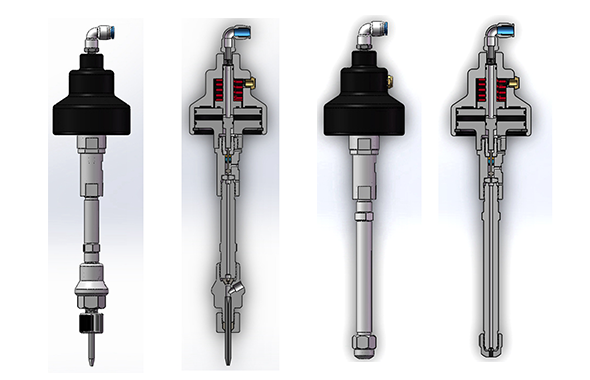

1) Ultra-high pressure water jet is divided into sand-based cutting and pure water cutting two main.

2) (Such as carbon, stainless steel, etc.), non-ferrous metals (such as copper, aluminum, titanium alloy, magnesium alloy, etc.), stone, glass, large thickness of composite materials (such as carbon fiber, glass fiber) and so on.

3) Pure water cutting mainly for rubber, foam, cloth, paper, rock wool, food and so on.

Structure features of Standard waterjet:

A high pressure water jet cutting machine is a tool used for slicing metal and other materials using a jet of water at high velocity and pressure. Featuring a low noise, no pollution, high precision and high reliability, our water jet cutting machine has been used in a variety of applications, including mining, automobile manufacturing, paper manufacturing, food, art and architecture. Water jet machines can be used to cut rubber, foam, plastic, composite, stone, tile, marble, glass and other materials.

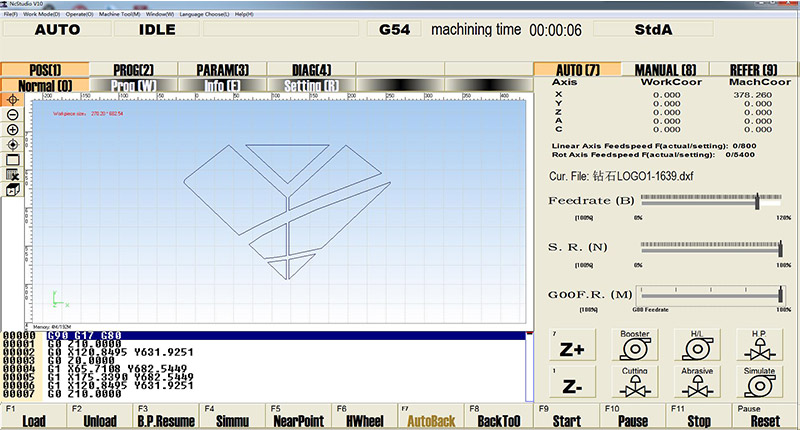

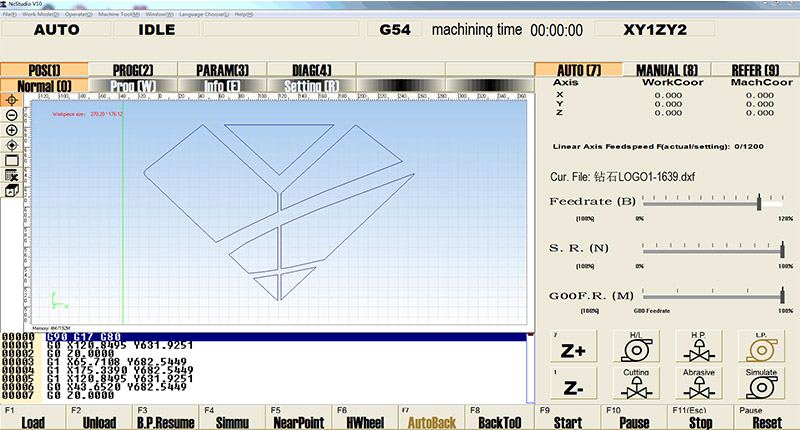

| CNC Specification | Number of Axes Supported 3-5axis |

| Control Signals | Plus Frequency 1MHZ Control Mode Position control Control Signal Differential signals Position Signal Type Plus+Direction |

| Communication | External PCI Interactive with Lambda PHOENIX bus |

| Spindle | Analog Voltage Output 0-10V |

| Tool Measurement | Tool Measurement Mode Fixed calibration, Mobile calibration,First calibration & Calibration after tool change |

| Compensation | Compensation Type Screw error compensation, Backlash compensation, AQE compensation, Tool compensation |

| Toolpath File | Supported File Format *.g/*.nc/*.u??/*.demo/*.iso/*.eng/*.cut/*.dxf/*.plt/*.txt |

| Operations | WCS Supporting WCS G54-G59 and Work Zero saving Processing Technology Array, Mirror&rotate, Cycle machining |

| Convenient Operation | Handwheel guide, Breakpoint resume, Tool selection |

| High-speed High-precision Optimization | Interpolation Algorithms T-type, S-type and LEP algorithms |

| Software Language | Chinese, English |

| Safety & Reliability | Sofeware Alarms Alarms of program error, operation error, over-travel error, PLC error, and IO communication error |

Specification parameters

Main Feature:

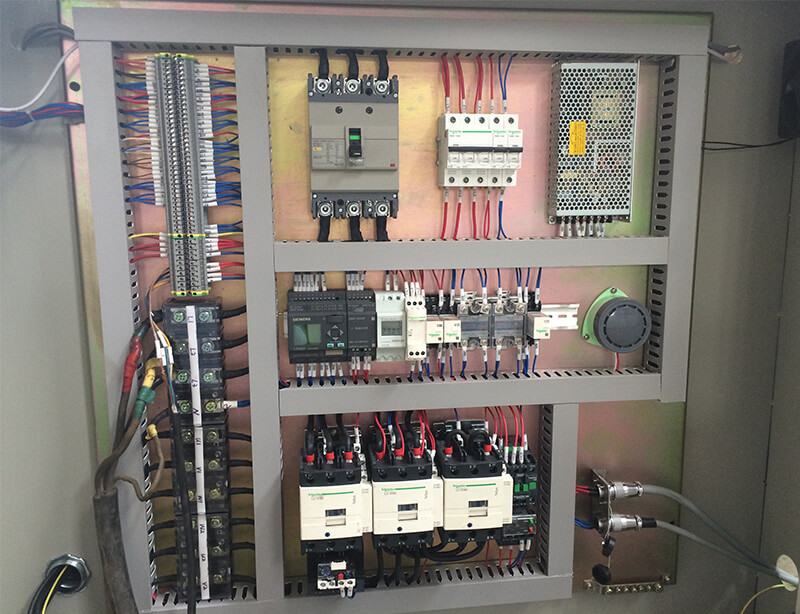

Control: PLC

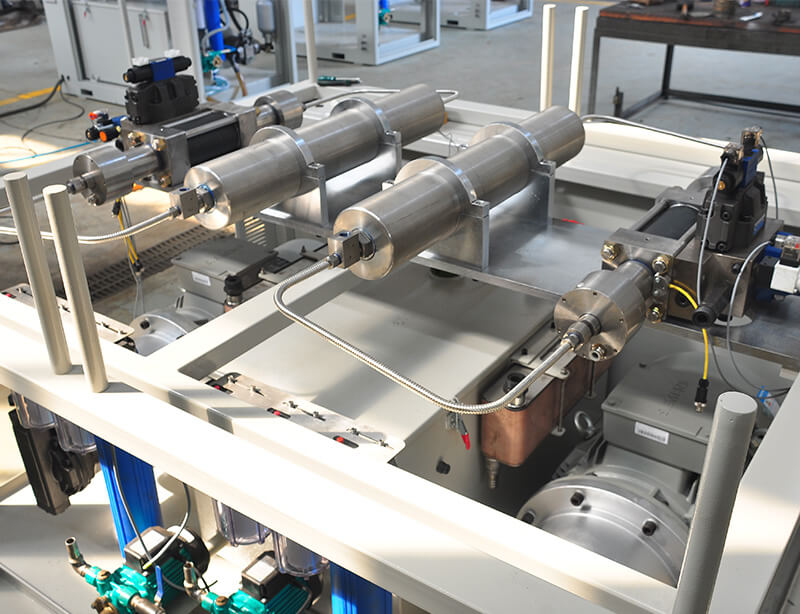

Shifting: electro-hydraulic

Control Cooling: cooler/oil heat exchanger

Inlet water filter accuracy: ≤0.45μm

Oil-return filter accuracy: 20 μm

Working temp: 0-50°c

Outlet: UNF 3/8″ Cooling in/out-let: NPT1″

Max orifice size: 0.33mm