Pipe Vessel Turning Rolls Tank Welding Rotator Positioning Equipment

Due to the fact that it does not require lifting or crane facilities, the use of a welding rotator increases production and reduces labour. For fabrication shops that work with light and heavy materials, welding rotators are ideal.

These welding machines can be used for both automatic and manual work, resulting in exceptionally high quality circumferential joints on shells. Along with welding pipelines, API flanges, heat exchangers, boilers, LPG bullet barrels, and pressure vessels are frequently used within the petroleum industry.

As welding fabrication workshops, welding rotators, or turning rolls, are useful accessories because they maintain constant and steady rotation speed regarding the welding head.

With a traveling carriage mounted welding head, the plates can also be rotated at various rates to attain the required position before being locked in place for longitudinal welding.

As well as welding in a vertical plane, turning rolls are also used to coat external or internal surfaces of hollow cylinders with metal fillers that have useful properties.

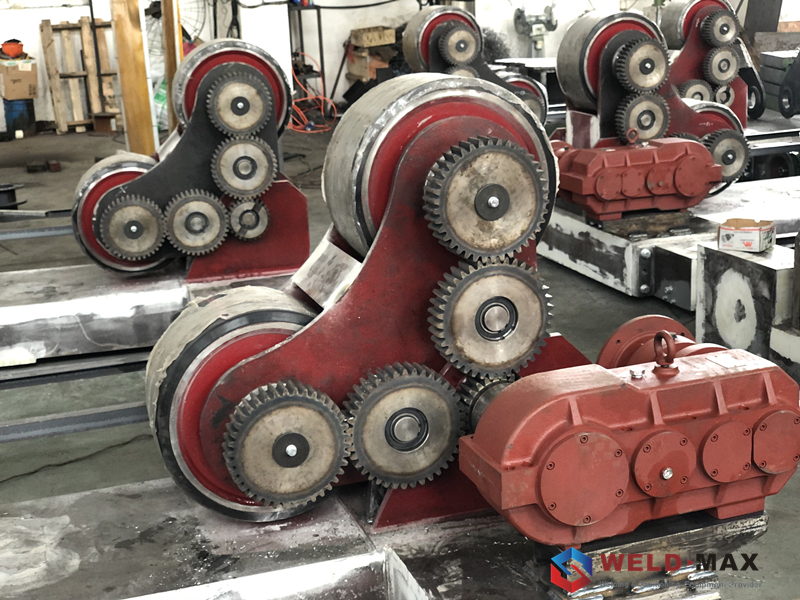

The driven or drive unit of a set of turning rolls usually includes two identical rolls, with one rotated by the motor and the other idle. The drive unit, also called the powered unit, can be either manual or automatic. An easily constructed frame attaches the rolls to the cylinders. The distance between the rolls can be adjusted to accommodate cylinders of various diameters.

In order to accept the cylindrical body that needs welding, these frames are usually placed apart on the shop floor.

Rotators can support a variety of weights as well as a variety of diameters. The materials, power type, and speed of a wheel are also characteristics of a wheel.

Before welding, the part should be able to turn freely on the rolls to prevent protrusions from interfering with the motion.

In order to avoid overloading, it’s also crucial to check the weight’s longitudinal distribution.

Instabilities that may cause the work piece to fall must be carefully monitored.

Minute positional errors can translate workpieces along their axes.